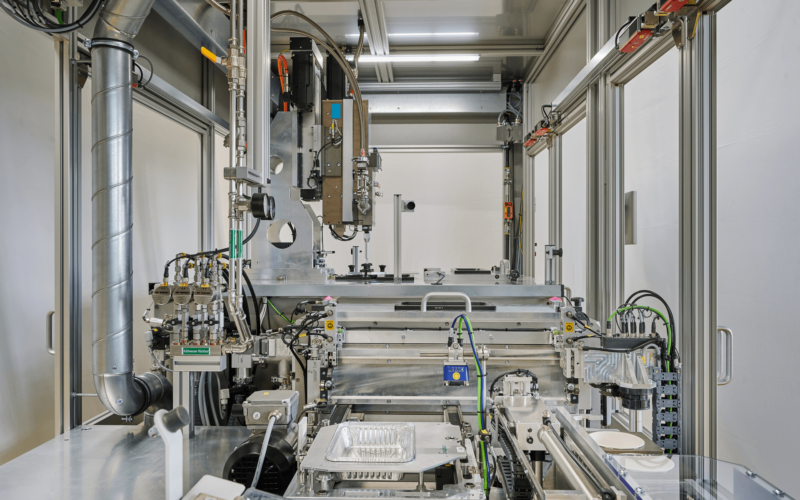

Our automated dispensing system features numerous advanced functions. They are able to precisely dispense both one-component (1K) and two-component (2K) materials and can even do this in a vacuum. The systems are equipped with highly dynamic axis systems or robots that enable both spot and path-controlled application. Other features include needle measurement, quantity control and needle cleaning, ensuring maximum accuracy and efficiency.

Process control is carried out using 2D or 3D evaluation to ensure consistent quality assurance. Depending on the application, a camera system is used to check the dispensed area, or a laser section sensor to determine the dispensed volume.

Our systems can be used as stand-alone solutions or integrated into an interlinked process, offering maximum flexibility for different production requirements.

The cycle time of the systems essentially depends on the individual dosing process. For vacuum dosing in interlinked systems, we offer special solutions to minimise cycle times.

We have already implemented the machine control with Siemens or Bosch systems. The systems can be interlinked with workpiece carriers as well as with rotary tables. The design of the systems is ESD-compliant.

For material preparation and dosing technology, we rely on well-known suppliers in this field and thus integrate seamlessly into your customised production system.

Processes:

- 1K dosing

- 2K dosing

- Vacuum dosing

- Optical test

- Geometric inspection

Technical data:

- Cycle time: Component-specific

- Siemens/Bosch control system

- Interlinking with workpiece carrier or rotary table

- Location: EU

- ESD version