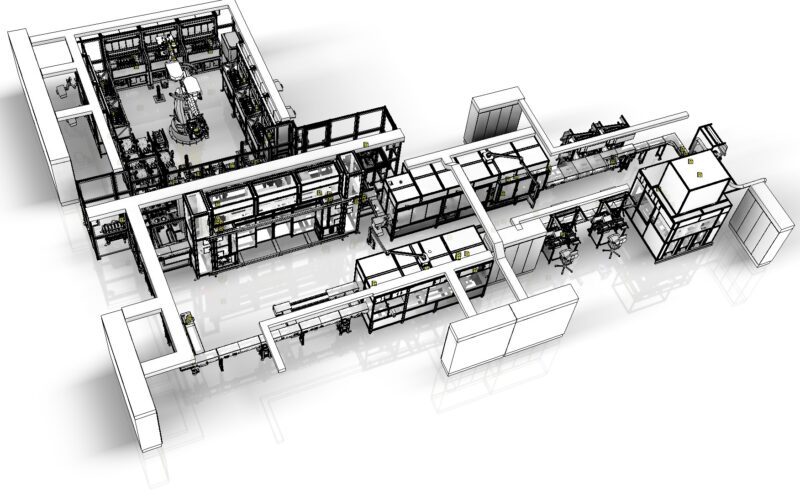

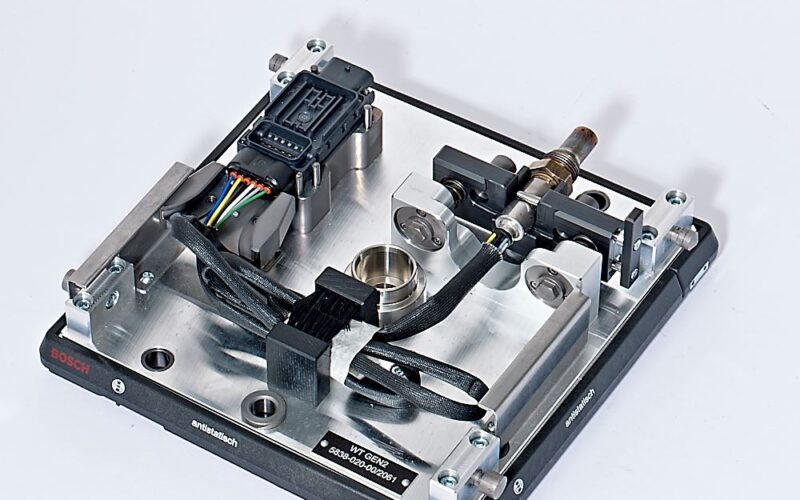

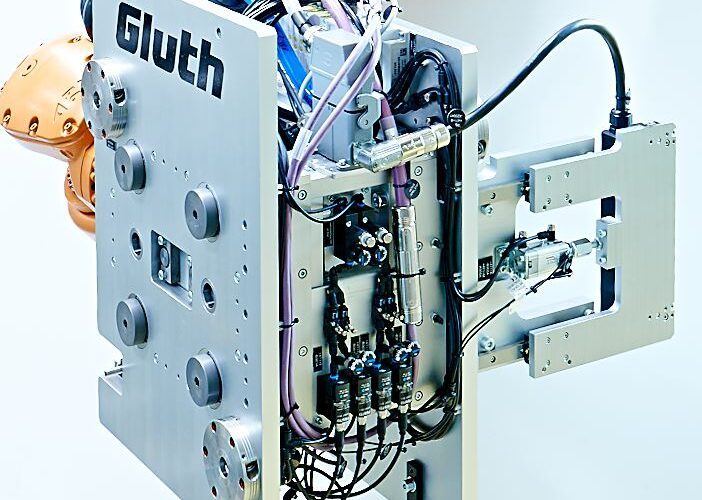

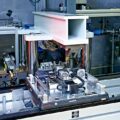

Our state-of-the-art system for the final assembly of exhaust gas sensors is a complex production system designed for maximum efficiency and flexibility. Our system combines a wide range of assembly and production processes with a complex testing task. The system includes a workpiece carrier transport on a transfer system as well as the collection of the workpiece carriers in cassettes, and interlinking by robots.

At the beginning, the sensor probe with cable and the control unit are manually positioned on a workpiece carrier by an operator.

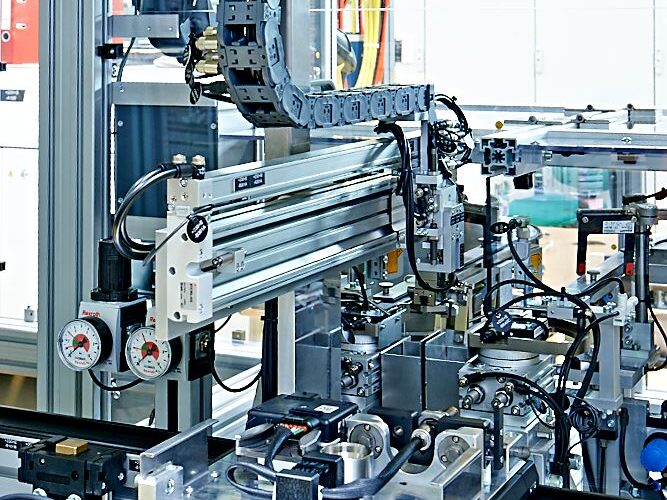

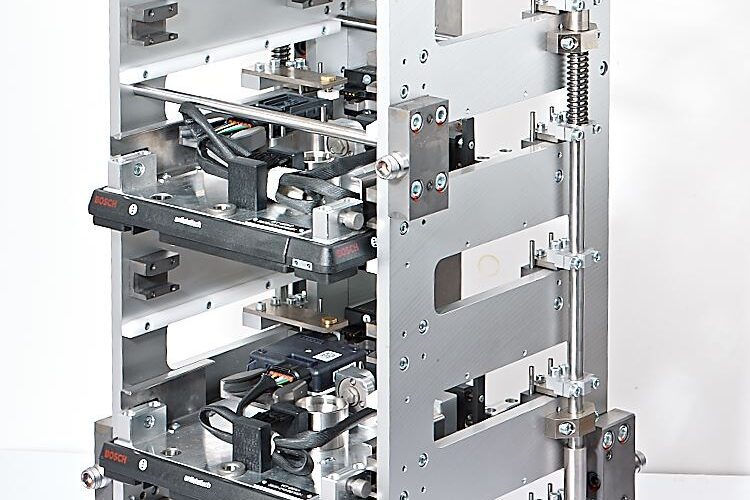

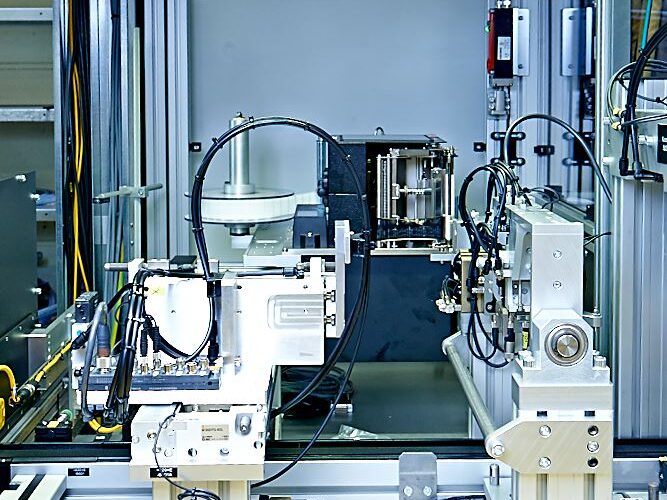

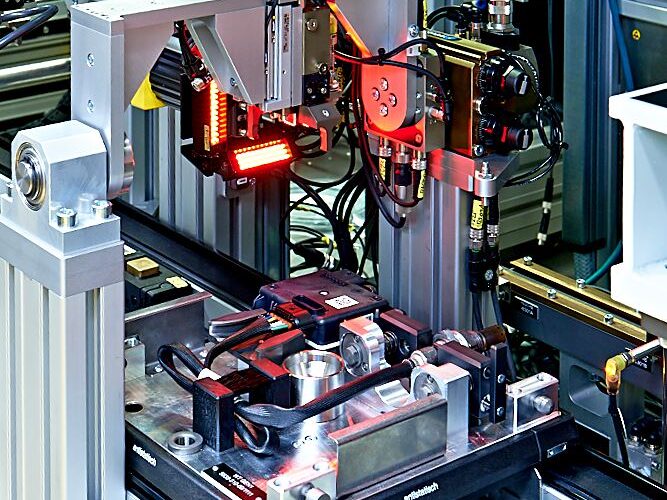

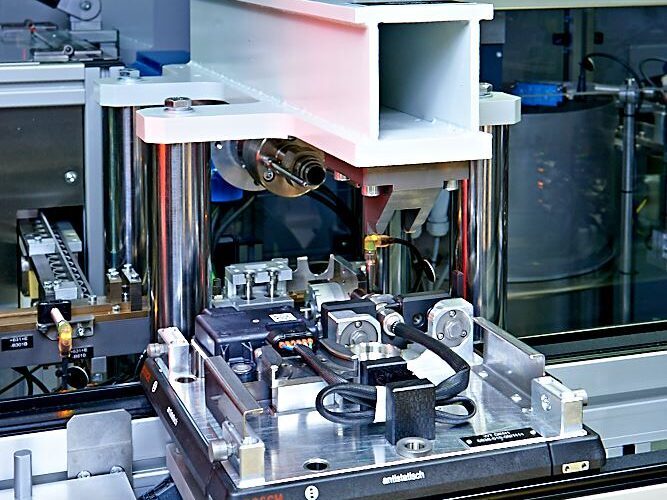

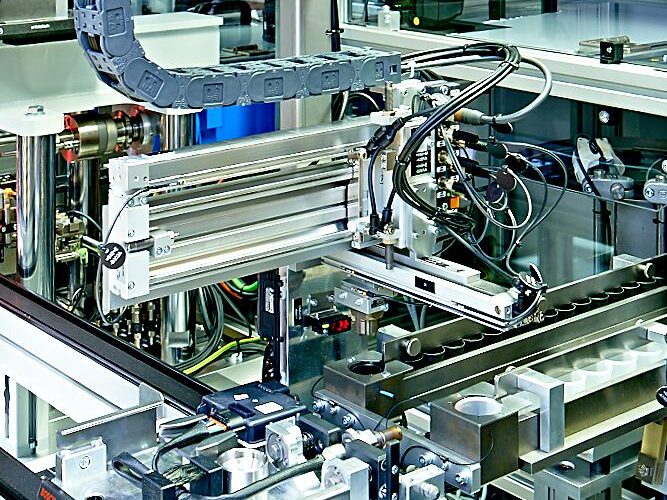

In the next step, the connector of the probe is joined with the control unit, force-displacement monitored by a servo press. This is followed by a pin welding station, in which the contacts of the connector and control unit are welded to ensure optimum electrical contact. At the next station, a plastic cover is placed on the control unit, where the cover is fed by a vibratory feeder. The cover is then welded onto the control unit using a laser transmission welding process. The workpiece carriers are then stacked together in cassettes to form a pack of 5. With 16 test cells, each with 5 test points, we were able to implement a system cycle of 6 seconds with a testing time of 300 seconds per sensor. Empty runs during changeover are not necessary with this system, which maximises production time and minimises downtime. At the end of the production chain, various end-of-line (EOL) processes are carried out. These include the labelling of the control unit to ensure clear identification and traceability. The sensor probe is then removed from the WT and lubricated using a 6-axis robot. During this, a precisely dosed quantity of a special high-temperature grease is applied to ensure optimum lubrication. The process is monitored cyclically to ensure a consistent quantity of grease and a high quality of the process. Finally, the finished sensor is placed in a protective cap to protect it from possible damage during transport and storage

Our systems are in operation worldwide, at locations in Germany, the EU, North America, Asia and India. The system is designed for different component variants and offers a flexible workpiece carrier that can be set up and expanded on a modular basis. The system is also equipped with component tracing and a master computer connection, which significantly improves traceability and production control. The system is controlled by a reliable Bosch control system.

Highlight:

The outstanding feature of this system is its innovative buffering of the workpiece carriers in special cassettes. This technology makes it possible to reduce the inspection times from the original 300 seconds to an impressive system cycle of just 6 seconds. Especially impressive are the complex logistics and the intelligent software, which not only allow the system to run empty automatically, but also automatic GRR inspections and the simultaneous handling of different workpiece types. This combination of efficiency and flexibility ensures that our system fulfils highest demands and achieves optimum production output.

Processes:

- Laser welding

- Plastic welding

- Labelling

- Gas testing

- Greasing

- Laser marking

Technical data:

- Cycle time: <6 seconds

- Bosch control

- Interlinking with robot and transfer system

- Location: Germany, EU North America, Asia, India

- ESD version