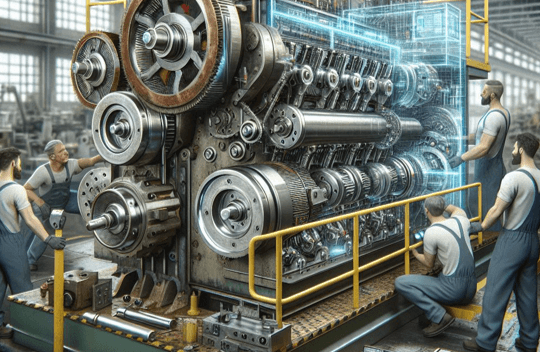

Retrofitting/conversion of existing systems

Has your production facility seen better days?

Your product is still selling well, but your machines are old and causing more and more problems?

Are you experiencing unplanned downtimes because components are failing and it is becoming increasingly difficult to find spare parts on the market as they are no longer being manufactured?

Often the manufacturer of the machine no longer exists and you do not know who could help?

We are the right partner for retrofitting your system.

A complete conversion of the machine may lead to a longer system downtime, but compared to a new system, up to 70% of the investment costs can be saved and the machine can continue to produce for many years. It is also possible to integrate new product variants into an existing system.

We have gained extensive experience in several completed projects. The control systems and peripheral devices used are often no longer available. When replacing individual components, it often turns out that communication between old and new components is no longer possible. It is therefore often advisable to replace all affected components in one large step.

We carry out a retrofit project in several steps:

- Initial consultation: We check whether a retrofit generally makes sense and estimate the necessary effort for a feasibility study.

- Feasibility study: We analyse your machine in detail and develop a plan for retrofitting the system. In particular, we analyse the components used, the status of the system documentation, the scope of the existing software and develop a strategy for the software upgrade. The result of this phase is a detailed quotation for your retrofit.

- Detailed retrofit project: We develop the task packages for the retrofit, procure the required materials and prepare the software. The aim is to keep the plant downtime as short as possible. The basis for this is perfect project management that takes all the needs of those involved into account.