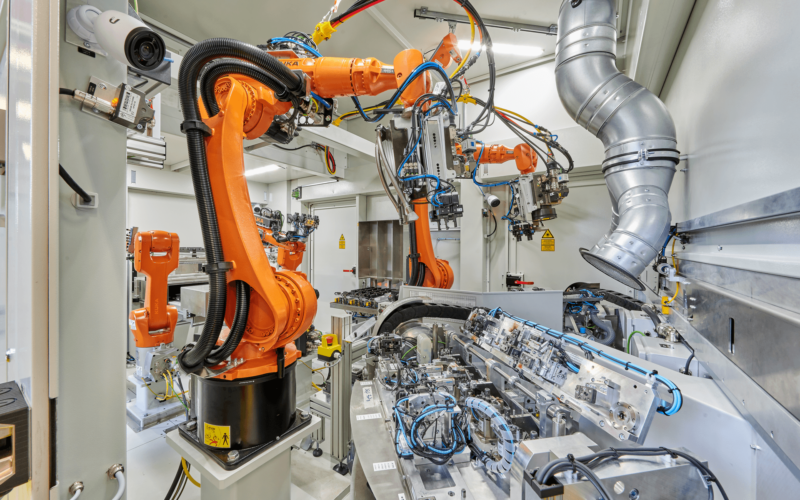

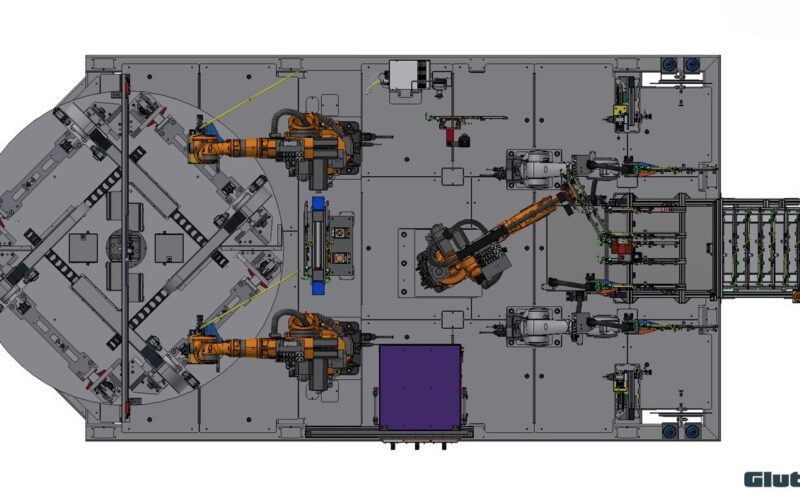

Our ultra-modern system for laser stapling and pasting sets new standards in system and fixture construction. The robot interlinking comprises five robots, which maximises efficiency and precision. These robots are designed to be arranged in a compact space, offering significant space savings. In addition, the robots can be easily reprogrammed, which ensures a high degree of flexibility when adapting to different production requirements.

A standout feature of this system is the robot-guided welding optics, which allows a wide range of positions and angles to be achieved with just one set of optics. This ensures high precision and quality of the weld seams. All this is complemented by the robot-guided tracing, which ensures that the material is applied evenly and precisely.

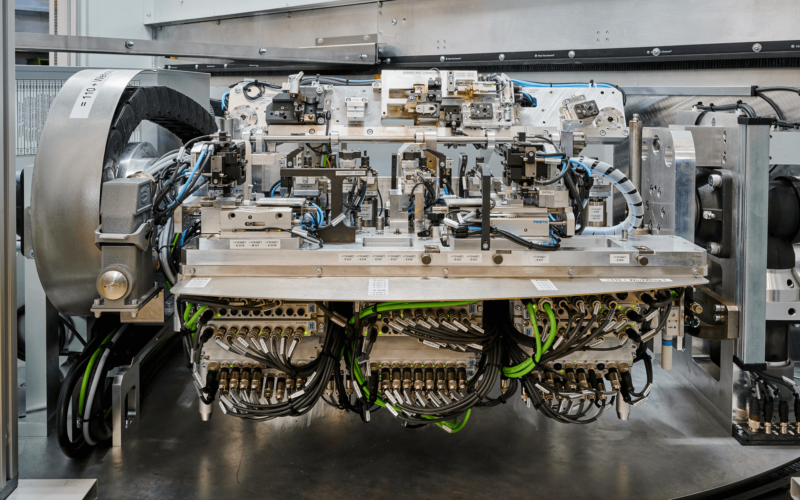

The system is equipped with highly complex, interchangeable clamping and positioning tools, which are located on a rotary table. This rotary table transports the parts into the laser area, ensuring a smooth and efficient process. Two loading stations ensure continuous operation, which significantly increases productivity. The ability to process four different types on one tool emphasises the versatility and adaptability of the system.

Another highlight is the walk-in laser cell, which is optimised for maintenance and cleaning work and provides a safe working environment. The compact and space-saving system concept enables optimum utilisation of the available space, which is particularly advantageous in confined production environments.

A special feature of the system is the virtual commissioning of the robots. Feasibility studies can be carried out as early as the development stage, enabling faster and more efficient commissioning. This not only reduces the development time, but also the costs and risks associated with physical commissioning.

The facility represents the state of the art and offers a perfect combination of innovation, flexibility and efficiency. It is a prime example of the advanced solutions we offer in plant and fixture construction and ensures that our customers always benefit from the best available technologies.

Processes:

- Laser welding

- Toolmaking

- Laser marking

- 1K dosing

- Optical control

Technical data:

- Cycle time: 20 seconds

- Siemens control system

- Interlinking with robot and rotary table

- Location: EU