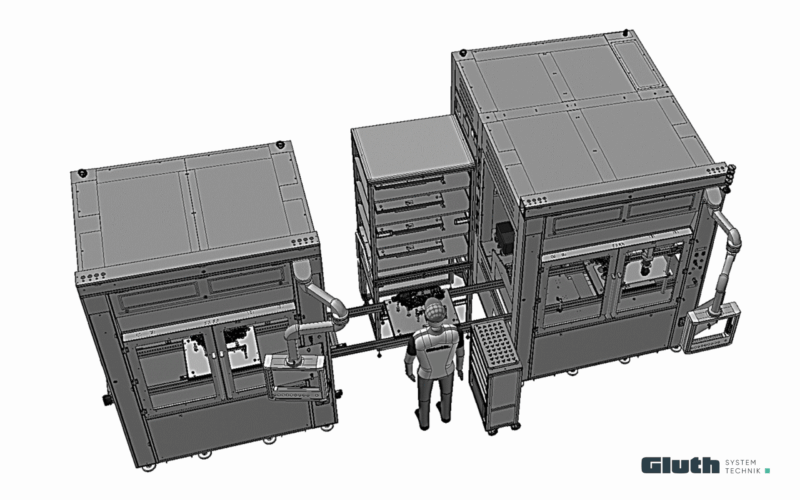

A semi-automated plant is a production facility that integrates both human labour and automated technologies. Unlike fully automated systems, which operate largely without human intervention, semi-automated systems still require human supervision and intervention. These systems are particularly useful in areas where human intelligence and flexibility are required to accomplish complex tasks

Advantages of semi-automated systems

- Flexibility

Semi-automated equipment can better adapt to changing production requirements, as human workers can quickly respond to new tasks and changes

- Cost savings

Investment costs are generally lower than for fully automated systems, as not all processes need to be automated

- Preservation of jobs

The combination of man and machine preserves jobs, which can be socially and economically beneficial

- Error reduction

Automated components can increase the precision and quality of production, while human workers can recognise and correct errors that machines may miss

- Faster amortisation

The lower investment costs and greater flexibility often lead to shorter amortisation times

- Scalability

Semi-automated systems can be gradually expanded and further automated as production requirements increase

This concept offers a balanced solution that takes advantage of both the benefits of automation and the flexibility and adaptability of human labour.