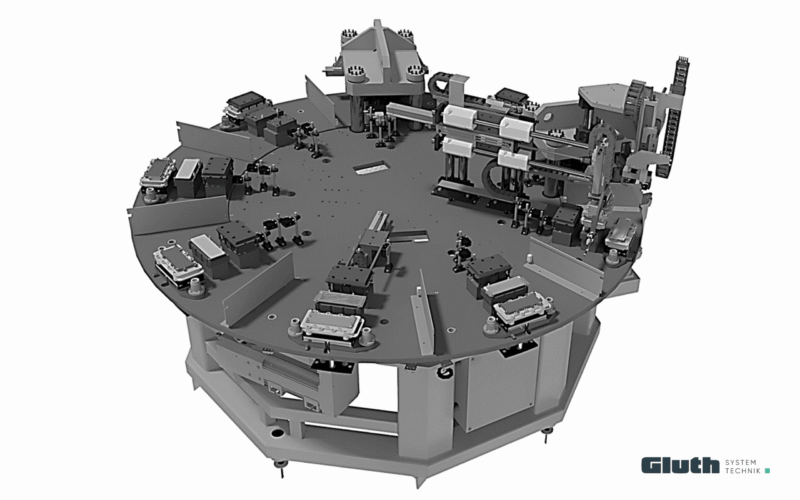

A rotary table concept in manufacturing plants is an efficient solution in which a rotating platform (the rotary table) is used to transport workpieces or tools to different processing stations. This type of system is particularly useful for processes that require high precision and repeatability.

A rotary table consists of a rotating platform that is moved by various drive systems such as a chain, friction wheel or central drive. Depending on the load and size, the platform can be supported either only in the centre by a central bearing or additionally by rollers. The media is fed through rotary feedthroughs in the centre.

- Space saving

Rotary tables have a compact design that uses the available space optimally. This is particularly advantageous in production environments with limited space.

- High precision

Thanks to the precise control of the rotary tables, workpieces can be positioned exactly. This results in greater accuracy during processing and assembly, which improves the quality of the end products.

- Flexibility

Rotary tables can be adapted to different production requirements and workpiece sizes. This makes them versatile and enables quick changeover to different production orders.

- Rapid cycle times

The short cycle times of rotary tables increase productivity, as workpieces can be moved quickly and efficiently from one station to the next. This reduces throughput times and increases the overall efficiency of the system.

- Simple integration

Rotary tables can be easily integrated into existing production lines. This enables seamless expansion and adaption of the system without the need for extensive conversion measures.

- Robustness

Rotary tables are generally durable and require little maintenance. Their robust design ensures high reliability and minimises downtime, reducing operating costs.

- Reduced set-up times

The quick and easy changeover to different production orders minimises the set-up times. This increases production flexibility and efficiency.

- Increased safety

The enclosed design of rotary tables minimises the risk of accidents and increases safety in the workplace. This is particularly important in automated production environments.

The concept can be adapted to the specific requirements of your customers and offers an efficient and precise solution for various manufacturing processes.