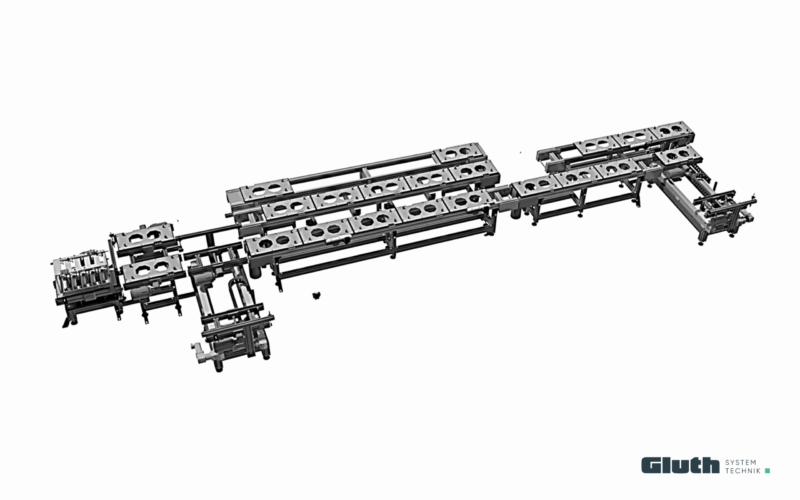

Transfer belts are integral components of modern production facilities that enable workpieces to be automatically transported between different processing stations. These systems typically consist of a combination of belt conveyors and workpiece carriers.

- Belt conveyors

These consist of endless, flexible belts that are tensioned over rollers or drums. They serve as drive elements that are powered by motors and enable the movement of workpieces along the production line. The belts can be made of different materials such as rubber, plastic or metal, depending on the requirements of the application.

- Workpiece carriers

These are specialised devices that hold the workpieces securely during transport. They are often modular in design and can be customised to the specific geometries and requirements of the workpieces. Workpiece carriers ensure precise positioning of the workpieces at the processing stations and enable repeatable processing.

- Increased productivity

Automation: The use of transfer systems minimises manual intervention, which increases production speed and shortens cycle times.

Continuous operation: Transfer systems enable a continuous flow of material, reducing downtime and maximising the utilisation of the production capacity.

- Flexibility

Modularity: Transfer systems have a modular design and can be easily adapted to different production requirements. This enables a quick transition to new products or processes.

Scalability: Systems can be expanded or modified to keep pace with growing production requirements.

- Quality assurance

Precise positioning: Workpiece carriers ensure that workpieces are positioned precisely at the processing stations, which increases the consistency and quality of the processing.

Reduction of errors: Automation and precise control of material flow minimise human error, resulting in higher product quality.

- Efficiency

Optimised material flow: Transfer systems optimise the flow of materials within the production facility, resulting in a more efficient use of resources.

Reduced manual intervention: Automating transport reduces the need for manual intervention, which increases production efficiency and safety.

- Low maintenance

Robustness: Modern transfer systems are robust and durable, which reduces maintenance costs and increases operational safety.

Easy maintenance: The system are designed to be easily maintained and repaired, minimising downtime.