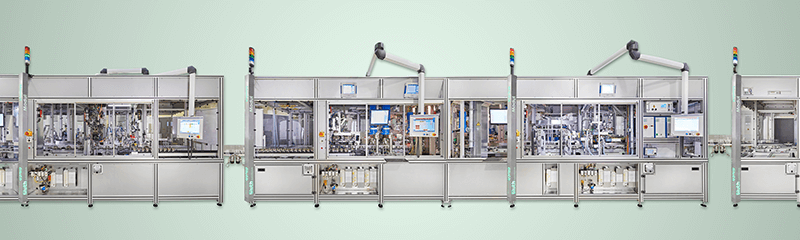

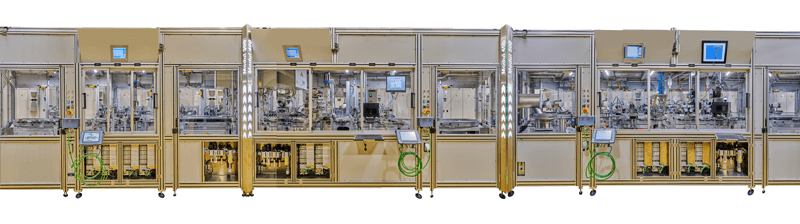

Our fully automated lines are a masterpiece in plant and fixture construction that impresses with its versatility and efficiency. The line integrates several linear cycle systems and can be interlinked via transfer systems or palletisers, enabling seamless and flexible production. With the ability to integrate over 50 individual processes, including coil winding in the automatic sequence, the line offers an impressive range of functions.

Particularly noteworthy is the component inspection during critical assembly steps, which ensures highest quality standards. The system can map variants by simple set-up or via type data, which enables rapid adaptation to different production requirements. Components can be fed both as bulk material or individual items in various moulds, which further increases flexibility.

Another highlight is the component tracing and the master computer connection, which ensure seamless traceability and efficient production control. With an impressive cycle time of just 3 to 5 seconds and Siemens or Bosch control systems, the line is extremely efficient and reliable.

Our lines operate worldwide at locations in Germany, North America and Asia, offering global support and service. This fully automated line is the ideal solution for companies that strive for maximum efficiency, flexibility and quality in their production.

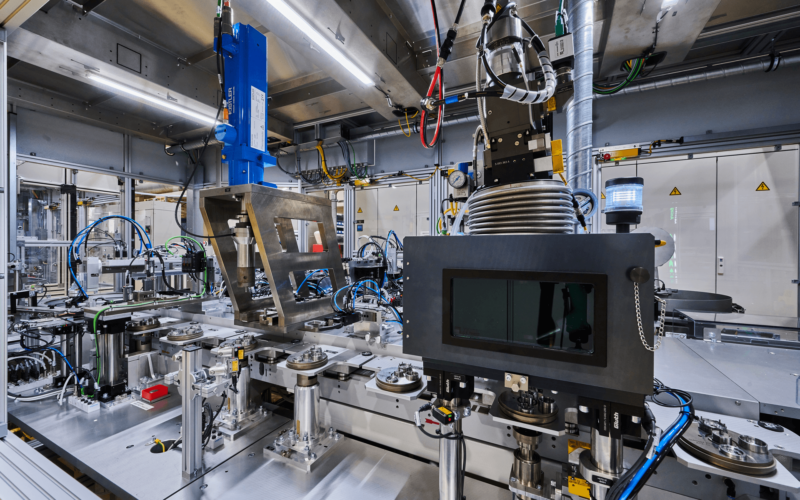

The system is specially designed to produce large quantities at high precision. It can process components with a maximum size of 50 x 50 mm and a maximum weight of 500 g. The design enables efficient and precise production that fulfils the high demands on quality and performance.

Processes:

- Laser welding

- Resistance welding

- Force-displacement press-fitting

- Flexible feeding

- Palletiser

- Characteristic curve test

- Leak test

Technical data:

- Cycle time: 3 .. 5 seconds

- Siemens/Bosch control system

- Interlinking with linear cycle system

- Location: Germany, North America, Asia