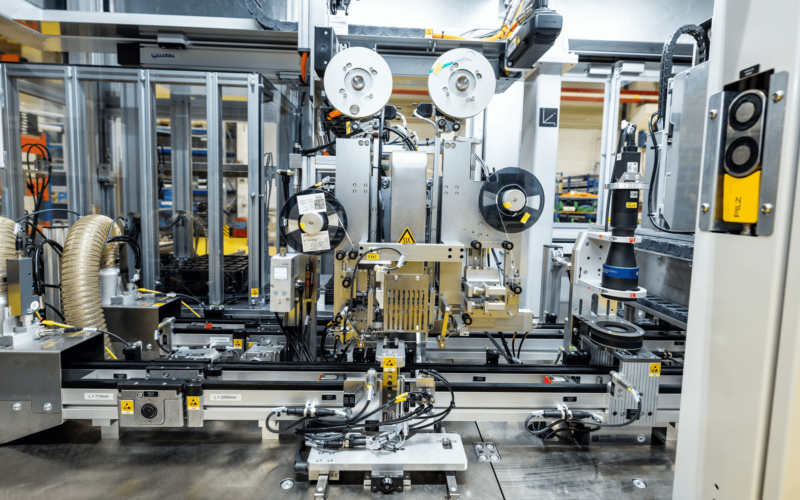

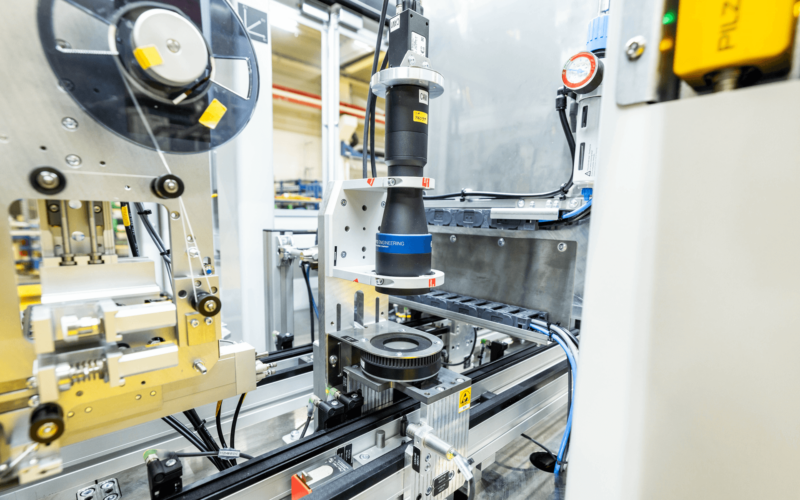

Our state-of-the-art assembly system for camera modules sets new standards in automated production and offers a wide range of innovative functions that ensure efficient and precise production. An outstanding feature of the system is the automatic assembly of flexible printed circuit boards (FPC). Supported by camera-assisted FPC positioning, it ensures maximum accuracy in the placement of flexible printed circuit boards, which significantly increases the quality and reliability of the end products.

In addition, the system comprises a range of other sophisticated processes. These include ACF bonding (Anisotropic Conductive Film), which ensures a secure and permanent connection between components, and camera checks, which enable continuous monitoring and quality assurance of the assembled modules. Resistance tests ensure that all electrical connections meet the required specifications, while labelling guarantees clear identification and traceability of each component.

Another highlight of the system is the workpiece carrier interlinking including data tracing. This function enables seamless traceability of each individual component throughout the entire production process, which significantly improves quality assurance and process optimisation. As the ACF bonding process cannot be displayed in the desired cycle time, we have integrated our unique manifold handling into the system. This allows us to integrate four ACF bonding stations into the process flow.

Cleaning stations for components and workpiece carriers with ionised air ensure cleanliness and avoid contamination. These stations reliably remove dust and particles that could impair the functionality of the sensitive camera modules. Especially the area between pre-bonding and FPC assembly is equipped with a fan filter unit in order to meet the specific cleanliness requirements for this area. After assembly and testing, the components are packed in trays, which ensures safe and orderly handling and protection of the modules during transport.

The system is also equipped with a master computer connection, which enables centralised control and monitoring of all processes. This ensures a high level of transparency and efficiency in production. Thanks to the Gluth cell construction kit, the system can be flexibly and modularly expanded, so it can adapt to different production requirements and volumes.

Particular attention was paid to the ESD-compliant design in order to protect sensitive electronic components from electrostatic discharges. This ensures high product quality and minimises the risk of damage during production.

The combination of advanced technology, sophisticated design and high flexibility makes our assembly system an ideal solution for the efficient and reliable production of camera modules. It not only offers a high production capacity, but also outstanding quality assurance and process control that meet the requirements of modern manufacturing.

Processes:

- Cleaning with ionised air

- Application of an ACF tape

- Camera-assisted FPC positioning

- ACF bonding

- Camera testing

- Resistance testing

- Labelling

- Packaging

Technical data:

- Cycle time 7 seconds

- Control system: Bosch Nexeed Control Plus

- Interlinking with Bosch workpiece carrier TS1

- Location: Germany

- ESD version