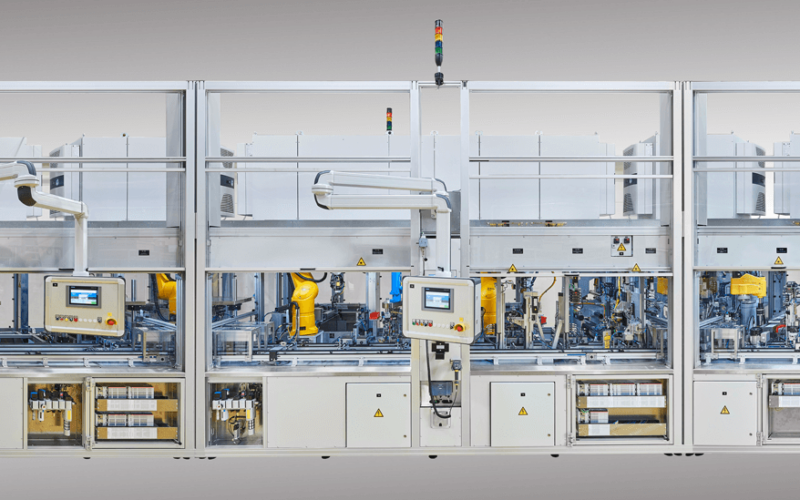

Our advanced automatic final assembly line for magnetic anchors is characterised by an impressive cycle time of just 10 seconds and a sophisticated interlinking with workpiece carriers and data tracing. The line is specifically designed to process different types of magnetic anchors, with the powerful Siemens system control allowing flexible and reliable control of all process steps.

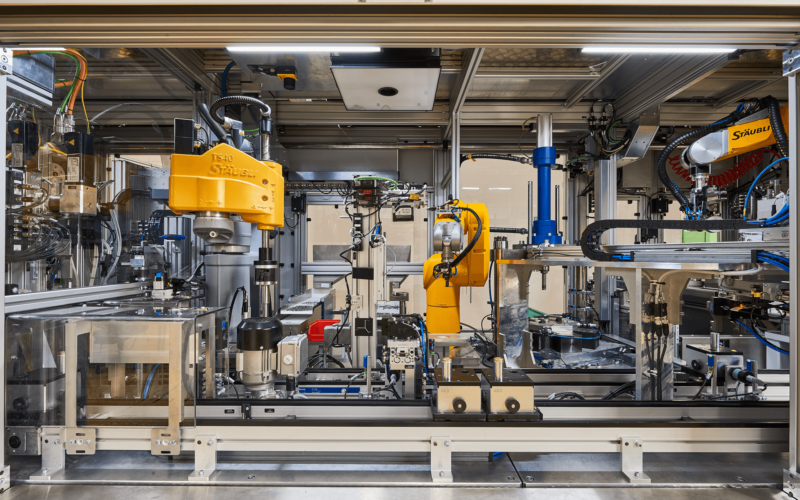

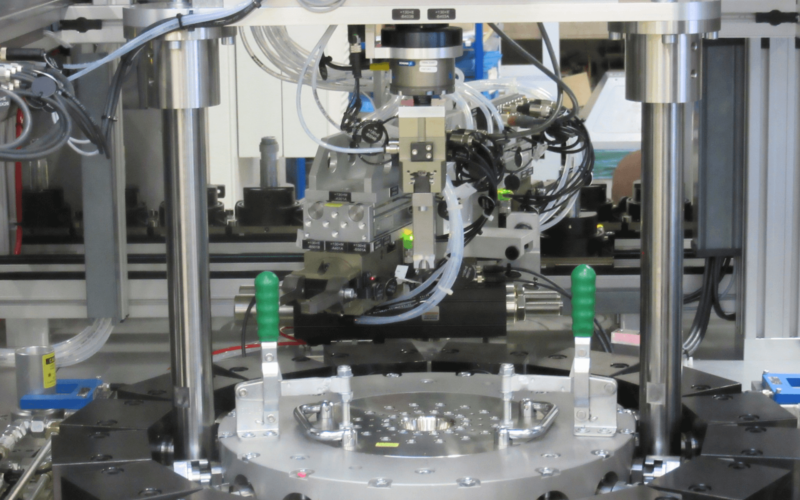

The system’s highly advanced processes include hydraulic stamping and crimping. These processes ensure a secure and permanent connection of the components. After stamping and crimping, an automatic visual inspection (AOI) of the stamping and crimping contour is carried out to ensure that the connections meet the high quality standards.

Another important process is the stamping, automatic joining and oiling of a sliding foil. These steps significantly improve the functionality and longevity of the magnetic anchors by reducing friction and minimising wear. The stamping, winding and joining of the foil is fully automated in the cycle of the line.

The automatic characteristic curve measurement is another highlight of the system, as it enables the electrical properties of the magnetic anchors to be checked precisely in real time. This ensures that only components that meet the strict quality requirements are processed further. A manual ejection area is integrated to allow flexible handling and inspection of the components. This is particularly useful for quality control and sorting out faulty parts.

The modular design of the system enables the individual process steps to be linked fully automatically. This not only ensures a high degree of flexibility and adaptability to different production requirements, but also efficient utilisation of the available space. To further minimise the space required, the control cabinets were placed on the roof of the system, which was designed to be walkable. This facilitates access to the control cabinets for maintenance and service work.

A master computer connection enables centralised control and monitoring of the entire system. In this way, a high level of transparency and efficiency in production is ensured, as all process data can be recorded and analysed in real time.

The combination of advanced technology, sophisticated design and high flexibility makes our final assembly line an ideal solution for an efficient and reliable production of magnetic anchors. The line offers not only a high production capacity, but also outstanding quality assurance and process control to meet the demands of modern manufacturing.

Processes:

- Hydraulic stamping

- Sliding foil stamping

- Automatic joining of sliding foils

- Oiling of sliding foil

- Hydraulic crimping of assembly

- Characteristic curve measurement

- Autom. Visual inspection of the stamping and crimping contours

Technical data:

- Cycle time 10 seconds

- Control system: Siemens

- Interlinking with workpiece carrier

- Location: EU