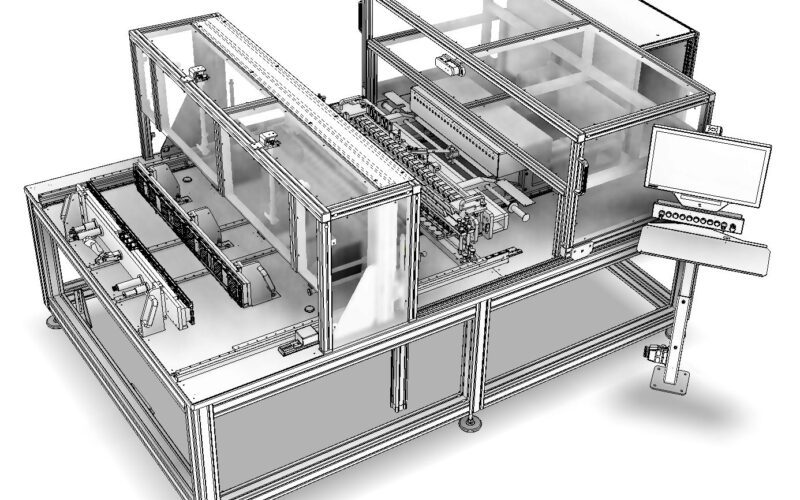

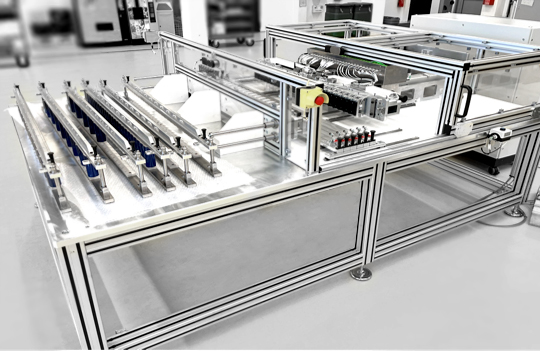

We not only offer fully automated production lines, but also manual workstations that are tailored to your production process. One example is our stacking device for battery cells, which is suitable for both prototyping and small series production.

The device allows manual insertion of battery cells and cooling plates, whereby the insertion is secured by a poka-yoke system. The pressing process takes place via a synchronised dual-spindle drive, which enables path-controlled wide-field joining with maximum force monitoring of the individual battery cells. In addition to the joining station, a curing station is available to round off the process.

The manual lifting of components is facilitated by pneumatic support, while optimised operating units ensure efficient manual single-piece production. Our solutions are available fully manual or with manual placement and automatic process to meet your specific requirements.

Processes:

- Manual placement

- Poka-yoke monitoring

- F/s joining

- Toolmaking

Technical data:

- 4 accumulators/day

- SEW drive

- Rexroth spindles

- Beckhoff control system

- Location Germany