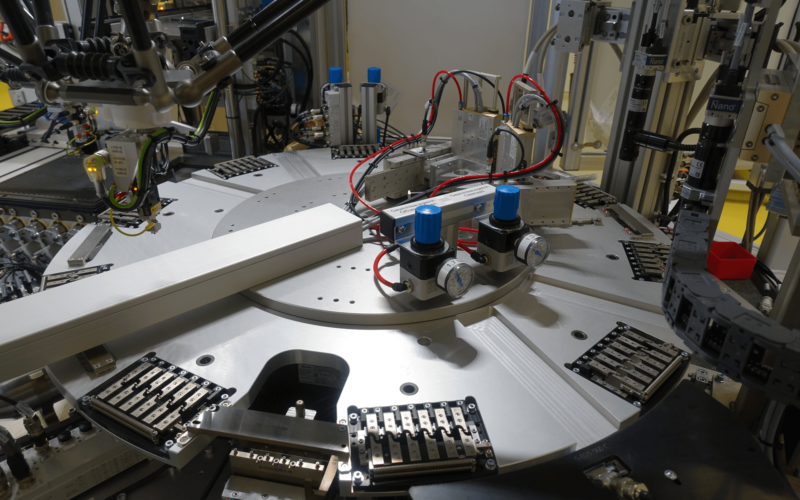

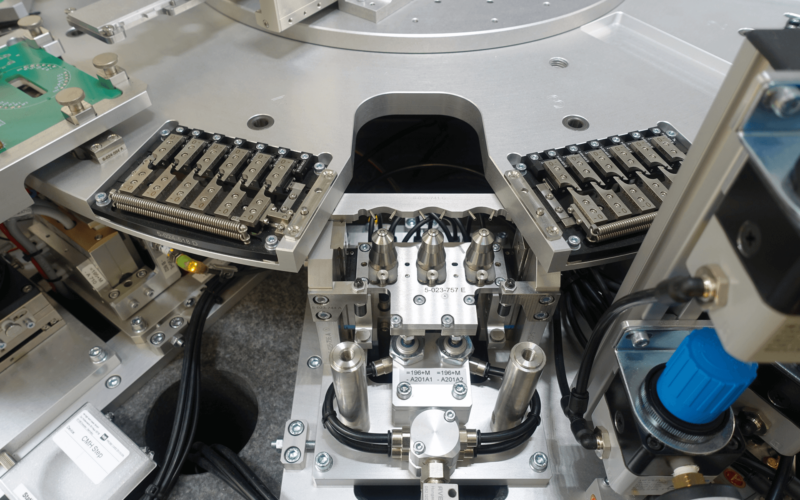

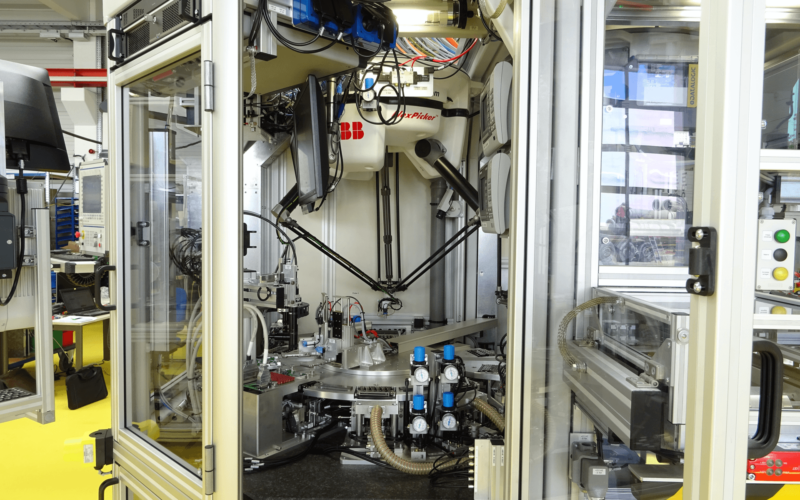

Our state-of-the-art system for laser cutting and testing of sensor elements sets new standards in precision and efficiency. The laser cutting head is controlled by a highly dynamic handling system for precise and fast processing. The integrated rotary table offers space for 10 holders, each of which can hold up to 6 sensor elements, ensuring a smooth and continuous production process.

A special highlight is the tactile burr measurement in the 0.01 mm range, which guarantees maximum precision. With handling times of less than one second per sensor element, FlexPicker delivers impressive speed and efficiency. Thanks to its compact design, the system can be easily integrated into existing production lines.

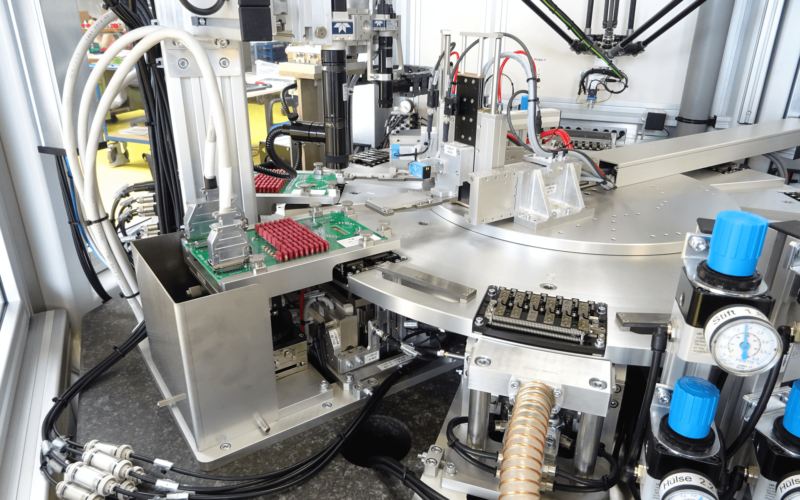

Automatic cut correction using a camera ensures consistently high cutting quality, while the sensitive vacuum suction pad handles the sensor elements gently and safely. The optical cut inspection on both sides ensures that each sensor element meets highest quality standards.

The smart blister handling without a set-up gap and the ESD-compliant design make the system particularly user-friendly and safe. In addition, the cleanroom design fulfils the requirements of ISO Class 6, making it ideal for use in sensitive production environments.

Processes:

- Laser cutting

- Geometric inspection

- Visual inspection

- Electrical inspection

- Component tracing

- Handling of lightweight components

Technical data:

- Cycle time: 1.2 seconds

- Bosch control

- Precitec optical control

- Handling with robot and rotary table

- Location: Germany

- ESD version